Welcome Back to the Erin Backpack Sew Along! We are now on Part 4: Create the Front Panel. If you missed any of the prior blog posts, you can find them below:

- Erin Backpack Introduction

- Sew Along Announcement with Fabric and Supply Information

- Part 1: Cutting, Interfacing and Hardware Prep

- Part 2: Make the Strap and Key Fob

- Part 3: Create the Back Panel

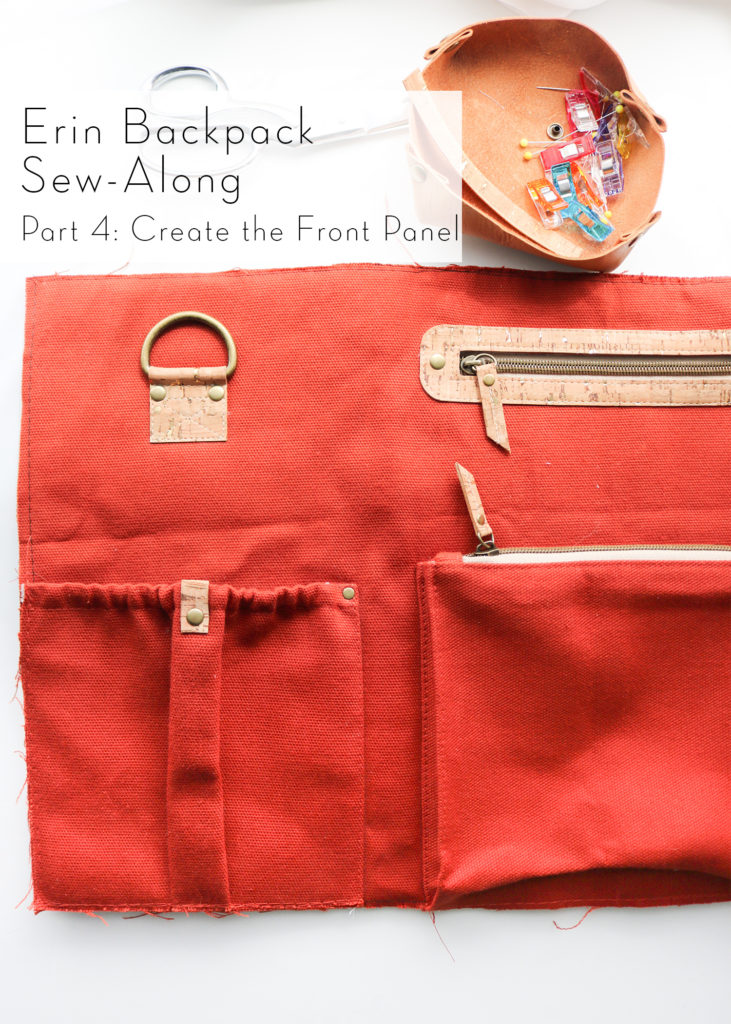

With this part, we are tackling the entire Front Panel with four different pockets. It seems overwhelming, but I’ve broken down all the pockets into 4 different short videos so you can work at your own pace.

WELT Zipper POCKET

At this point, the Front Panel is the only pattern piece left that hasn’t been basted to foam. This is added later because creating the Front Welt Pocket through foam would produce so much bulk and be very difficult to work with. I love all of you too much to put you through the extra wrestling and time spent trimming back foam! Ha!

I know you will ask me about the zipper pulls used on my bag 😉 These zippers are from MyHandmadeSpace and yes, I made the tabs myself! They are approximately 3/8″ x 4″ folded in half and secured with a seam straight up the center. I added a rivet to balance out the look with the rest of my bag. These are SUCH a great option to really personalize your bag. I’m so glad I bought them as a stash option!

Now let’s get to work. Click into the video about to watch how the Welt Zipper Pocket is created. Please note the following from the video:

- I am using “Craft” Tape as an alternative to Wonder Tape. This is only 1/8″ wide, but is permanent. With the coating on the canvas, I wanted to use a tape that was a little stronger than Wonder Tape. So, to avoid human error, I like to add this directly to the zipper tape first, and not to the lining.

- While adding on the Zipper Plate, I used glue instead of Wonder Tape. Again, I was looking for something stronger I could sew through and unfortunately, Craft Tape cannot be sewn through. (Your needle would gum up.)

- I’m adding the rivets earlier than the instructions. I don’t know why….but I started going by memory without checking instructions and went out of order. (This is what I get for not checking!) There is not a huge difference if you add them before closing the pocket lining or waiting until after the foam is basted on. Per the instruction, my intent to add them post foam, was to have extra anchor points against the foam to keep it from separating with the Front Panel. But there are many other points anchoring the foam to the main fabric with the rest of the pockets and Front Strap Tabs.

TIP: When I sew through an accent fabric and want to minimize punctures, I like to pull the threads through for a clean continuous line of stitches. However, from the back, I don’t want the threads just hanging inside. So, I knot the threads and use a light dab of glue to seal them against the fabric. I like to leave the tails long so that they will be sewn into the pocket later on.

SIDE ELASTIC POCKETS

With untreated fabric, interfacing would’ve been fused to the part of the Elastic Side Pocket facing the bag, as seen above on the left. But, since I’m using a heavy treated fabric, I cannot add heat and fuse to it. So you will see there is no interfacing to indicate the wrong side of the fabric in the video below.

Click the video to watch how to make and attach the Elastic Side Pockets. Please note the following:

- For extra durability, I demonstrate how to sew the pocket with an extra triangle at the top of the seam. This helps reinforce that area since it will be pulled on heavily.

- The size of the rivet used in the triangle has a 6mm cap and is not included in my hardware kit. I thought I would just make it a little different as to not compete with the added embellishment. This is the same size I use on the zipper pulls as well

- As an option, you can add in accent fabric with rivets as extra way to highlight pockets. It was an afterthought when making my waxed canvas sample seen here, but I wanted to show you the steps just in case you wanted to add them as well!

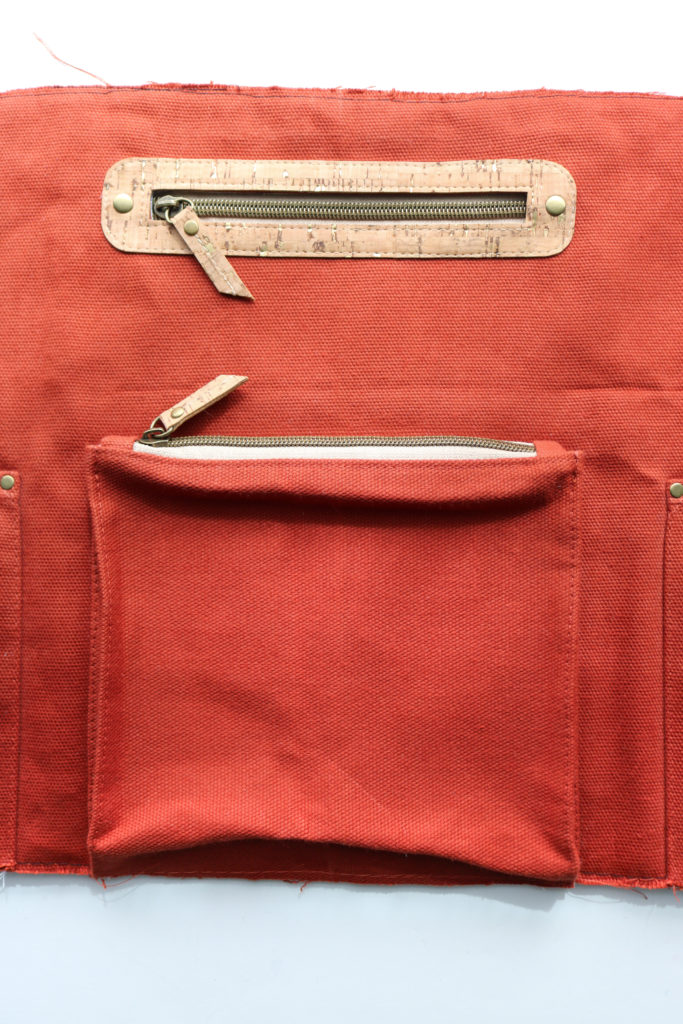

POP-OUT POCKET

If I am in a clothing store, I will always take a look at it’s bag section. I like to see what’s popular and if there are any outstanding features. Well, I saw a 3-D pocket similar to this one that I was determined to figure out on my own because I thought it was a unique way to create one. With a home machine, my design had to be changed, but the essence is there. Now, I get to share with all of you how figured out this pocket construction for my bag-makers!

Please click into the video above to view and note the following:

- When finishing the edge of the Zipper (that’s sewn directly to the Front Panel,) can just zig-zag along the zipper tabs. But since I primarily work on a straight stitch machine, it would require me to set up a machine. With the content being so heavy this week, I went with the serger that sits right next to my regular machine.

- When attaching the Zipper to the Front Panel, I switched feet on the second seam to get a little closer to the teeth and clear the overlock stitching

- During the filming, I lost a few segments when attaching the sides down to the Front Panel. I had to re-film those parts, but the Front Panel was already completed. So you will see that there are no hanging bits of fabric as part if the instructions. You might even see some of the Front Strap Tabs.

FRONT STRAP TABS

These Front Strap Tabs are for the cross-body and shoulder carrying options. So all the weight of the bag will be on these spots. That is why there is so much reinforcement stitching, as well as the added rivets. You don’t want these ripping out later, so take your time on every stitch!

Click into the video above to watch hoe to attach the Front Strap Tabs and note the following:

- I work with both my Teflon and Zipper Feet. I don’t call out the changes, but you can see them in the video

- For a clean finish, I always like to leave long thread tails and pull them to the back. With several knots and a dab of glue, those seams will hold just as well as several back-stitches.

Although a hardware press is a great tool, this is one case when a manual setting tool is better than a press. The dies require at least an 1/8″ clearance around the rivet caps whereas you hardly need any clearance with the tool seen above. There are some projects where there isn’t enough throat space with a press to install as well. So don’t ever get rid of those setting tools!

CONGRATULATIONS on finishing this Part 4 beast! You are more than half-way done now and doing great! Check back next week for Part 5: Making the Lining.

Happy Sewing!

Cristy

Please note, this post contains affiliate links. Please refer to my Disclosures for additional information.