A few months ago, I had the amazing opportunity of taking one of Sara Lawson’s bag-making classes…at my local quilt shop! I’ve been trying to attend one of her retreats for awhile and was so glad she came to Columbus. Sara designs some pretty fantastic bags and accessories through her business, Sew Sweetness. The Aeroplane bag was one of my first names and you can read about it here.

We have worked together in the past and I have a few guest posts on her blog. There is one from Purse-Palooza which you can read about here. I also wrote a review on a Craftsy Tailoring class which you can read about here. Sara is such a sweet and humble person but she’s such a rockstar to us bagineers!

I have to admit, the Appaloosa bag (aff link) would not have been my choice for a class with Sara. But I completely understand the bag we make has to be done in the time allotted, which was about 6 hrs. However, I found it as my own personal challenge to try to make this pattern, more “me.”

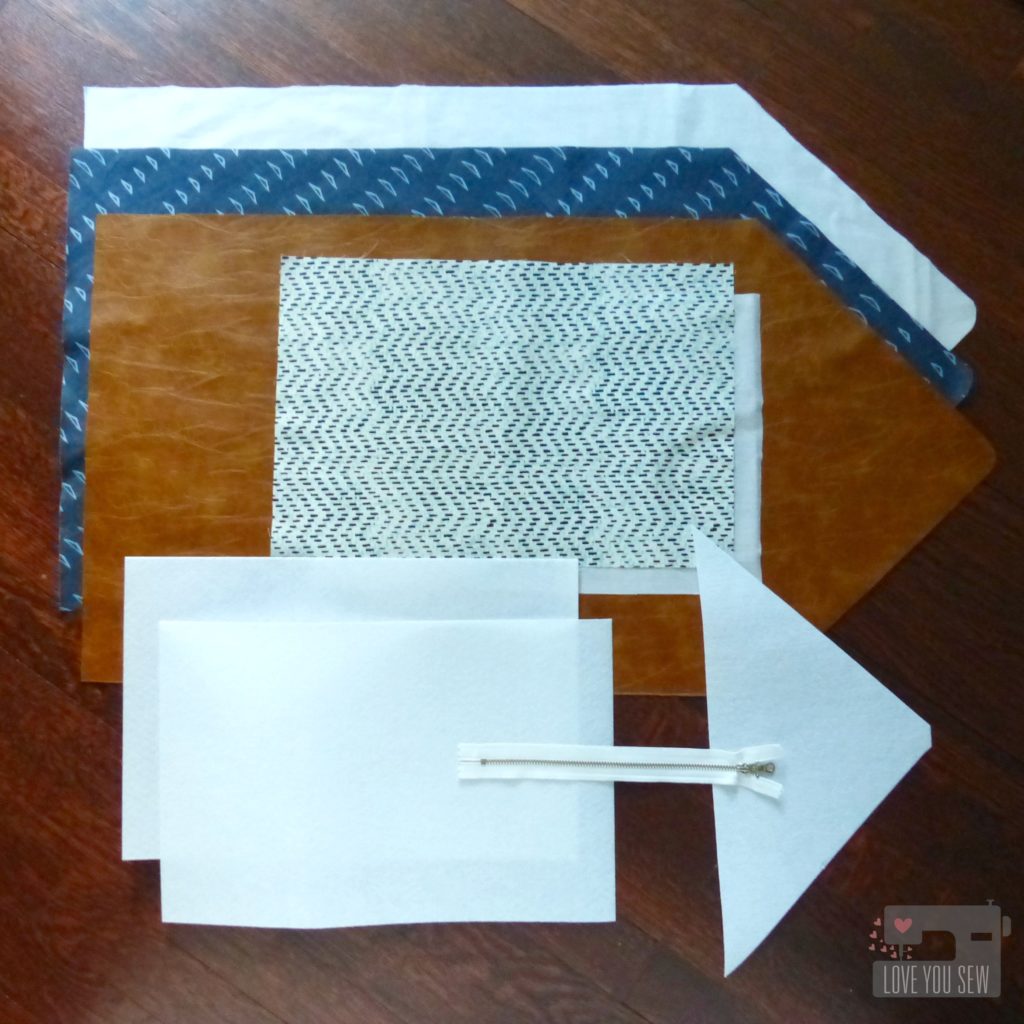

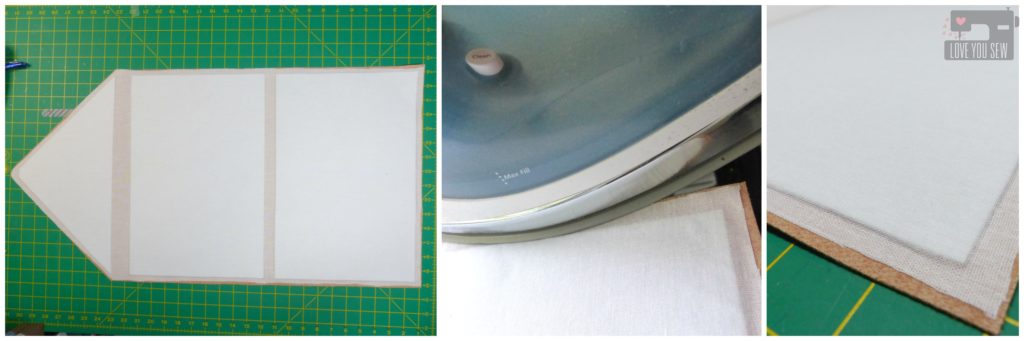

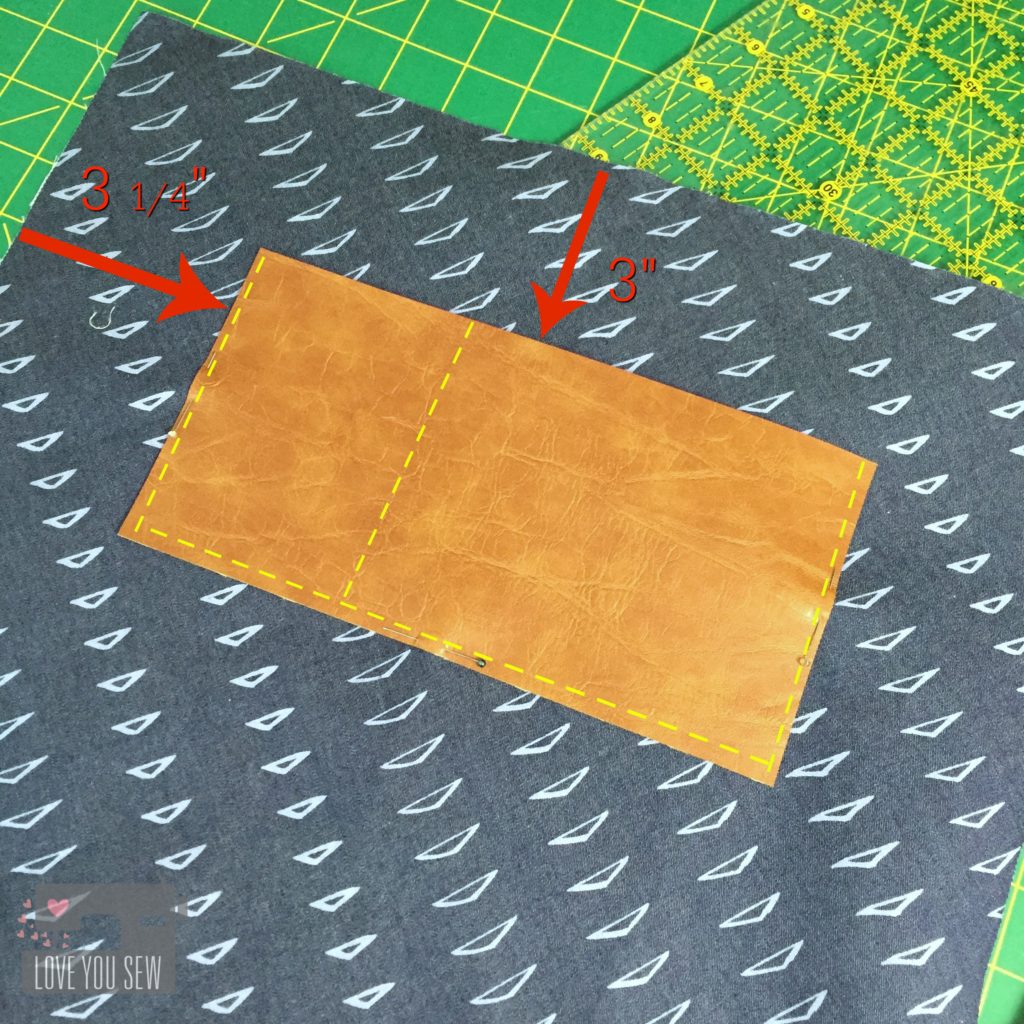

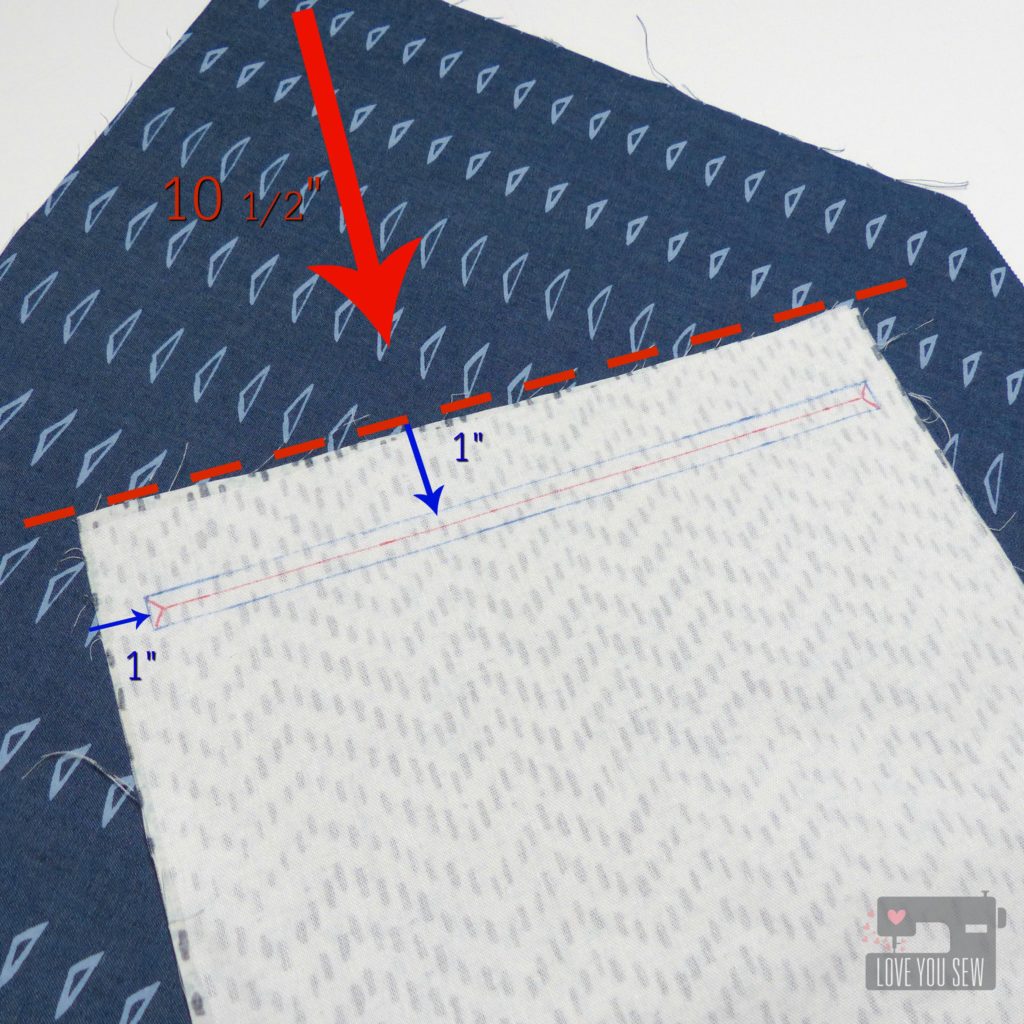

I used a light weight black denim by Robert Kaufman as my main fabric with Carolyn Friedlander’s Euclid as the lining. This would keep the bag modern and pretty versatile with any wardrobe. And since I was using the black denim, I made sure to use black Soft and Stable in the construction of the bag. Otherwise, you run the risk of the natural colored foam peeking though the needle holes.

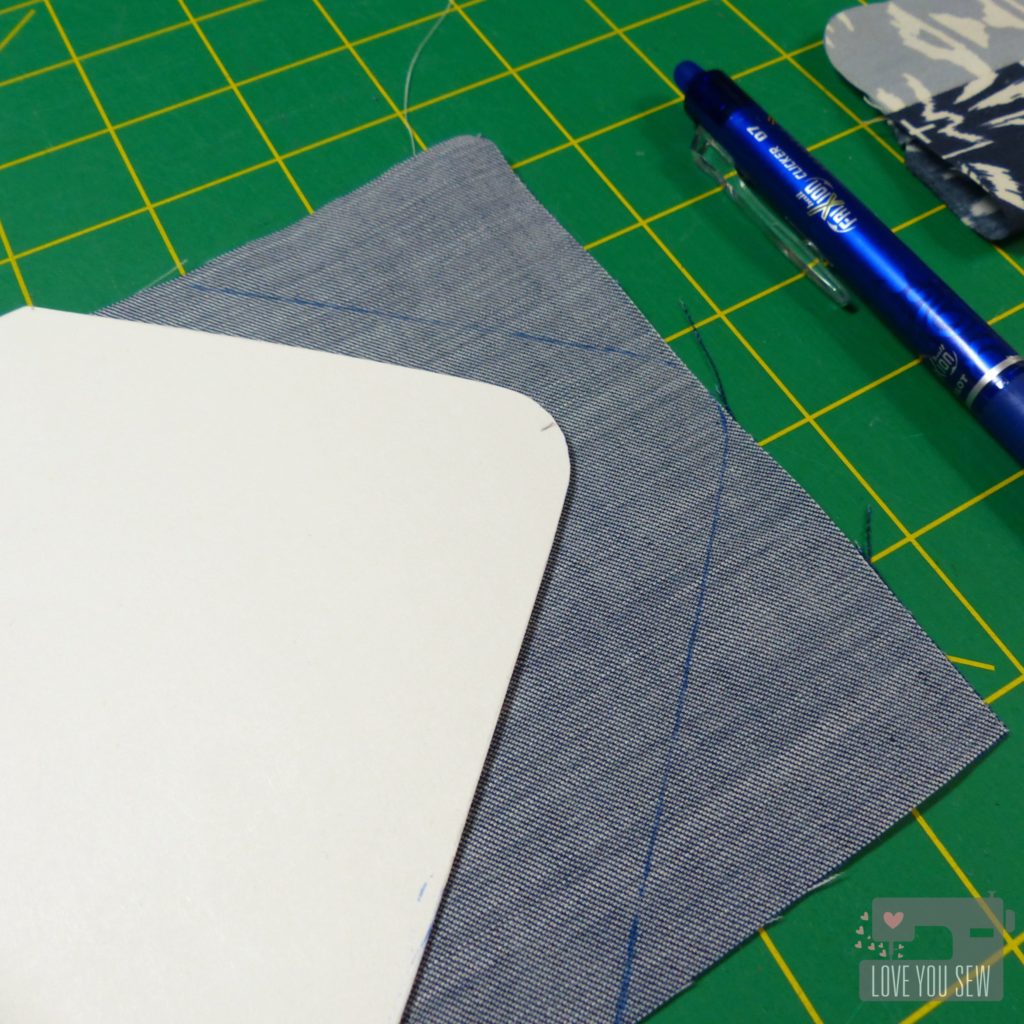

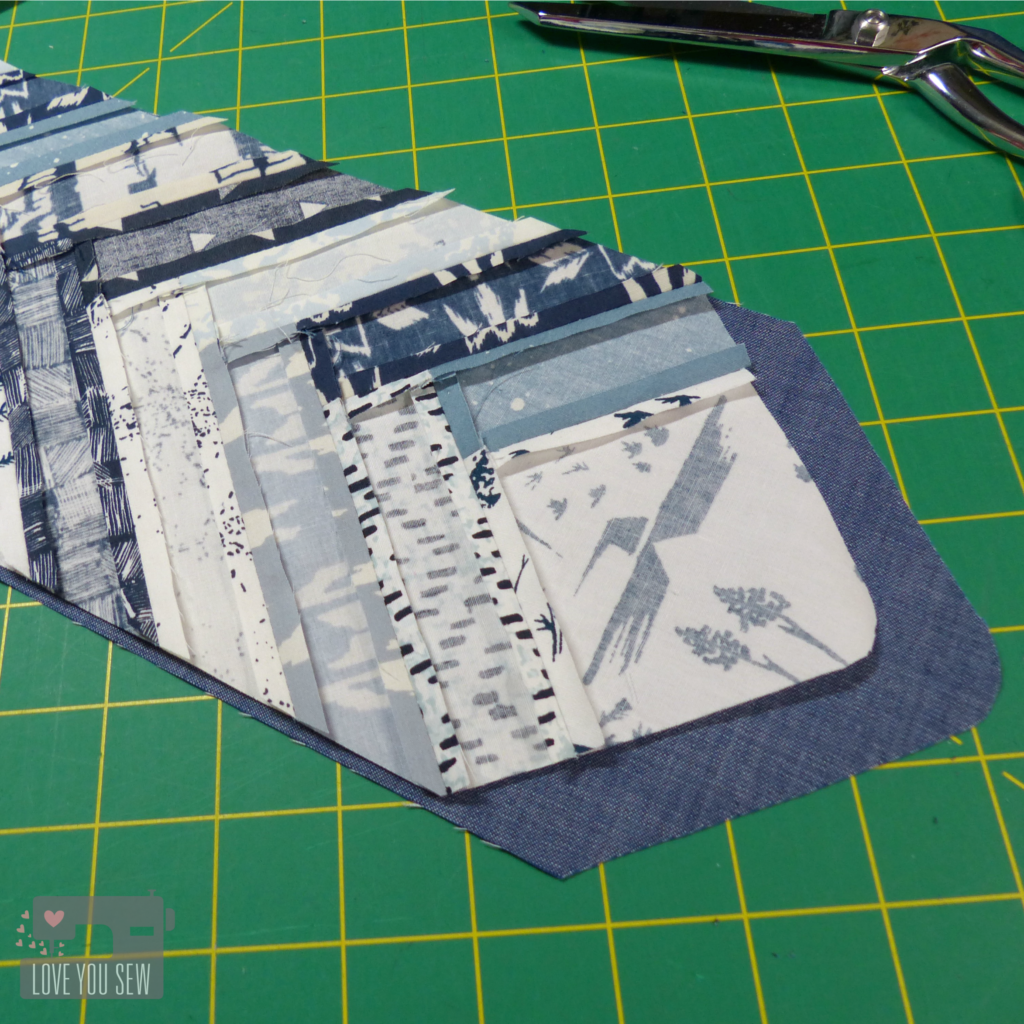

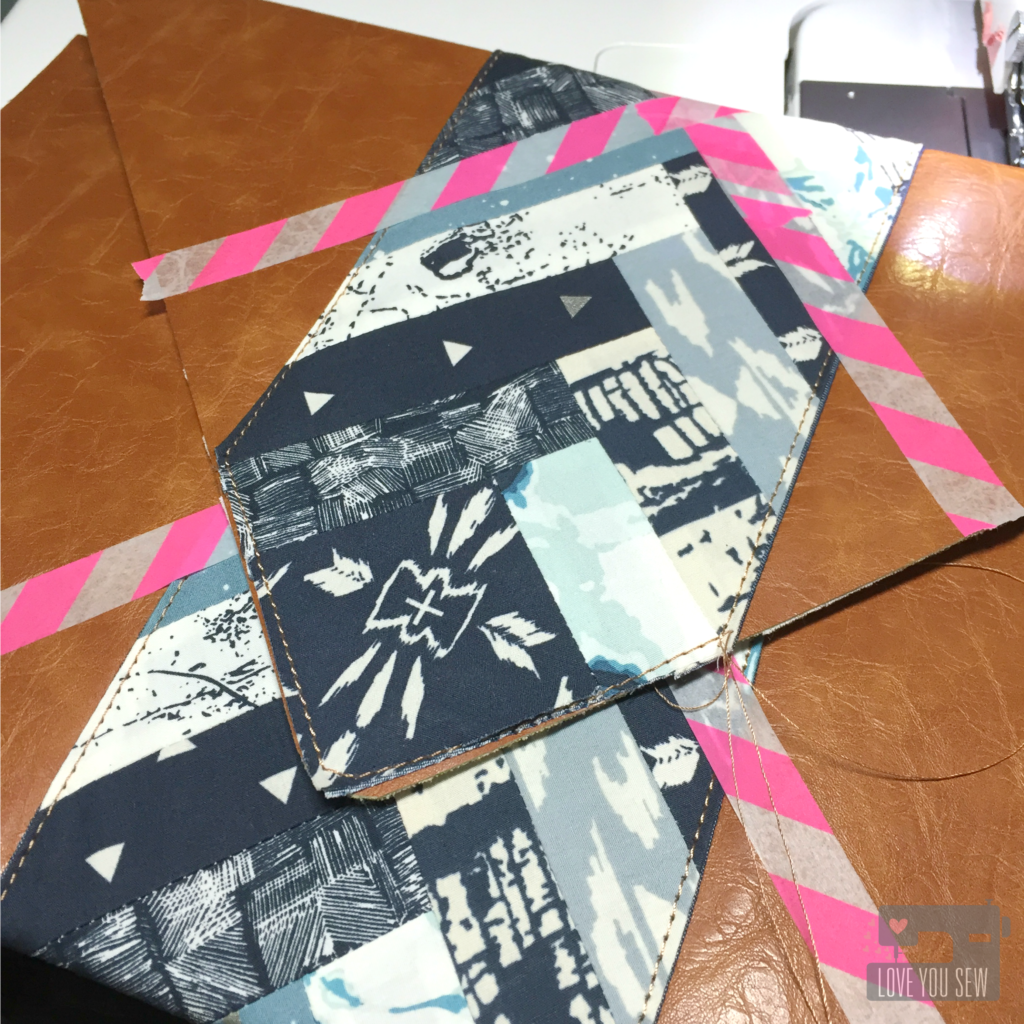

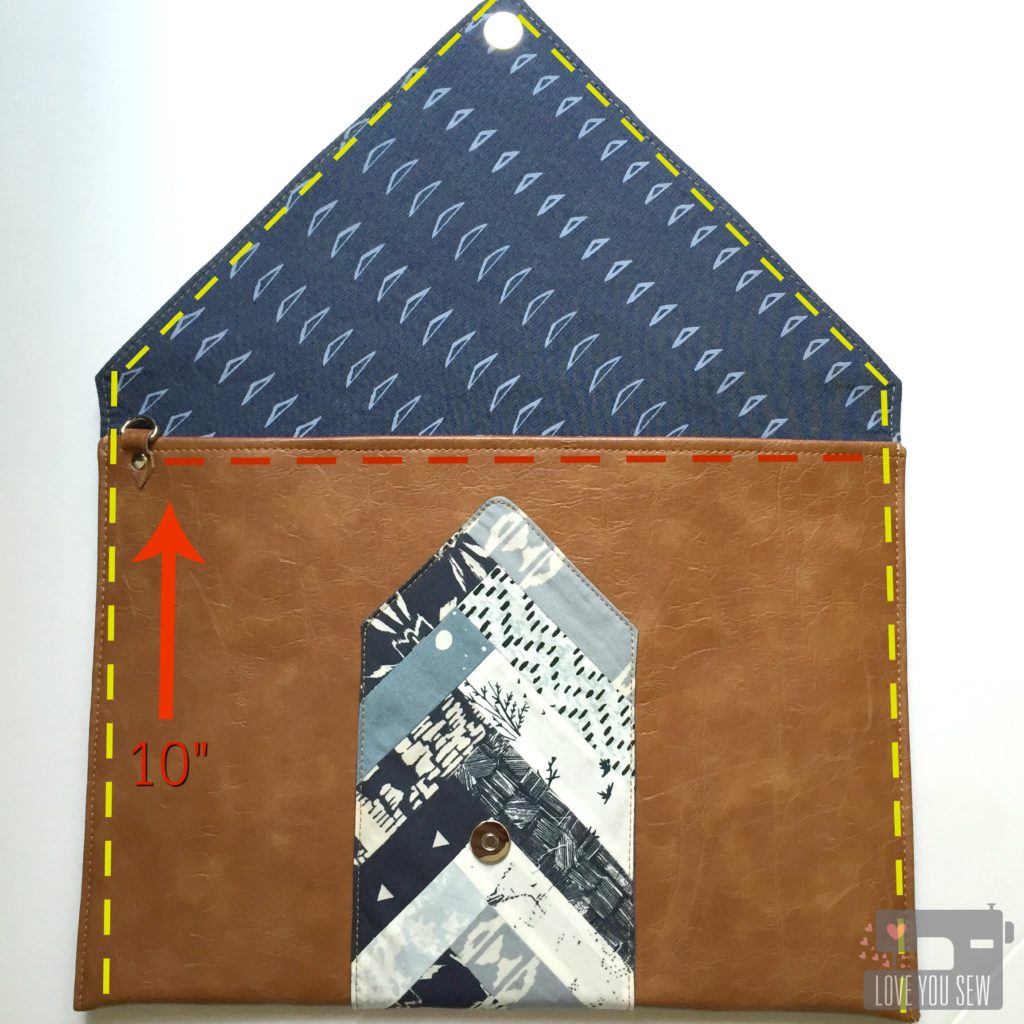

With the black denim being pretty plain, I just had to do a little bag quilting. (You know me!) I took some inspiration from current Rebecca Minkoff bags to try to pull off something very modern and on-trend. With the pattern calling for all of the Soft and Stable, I knew the texture would be perfect on this bag. I made a simple herringbone design using my favorite Chalk-pencil. You can still see the marks on the picture above. The lines just erase right off when you are finished.

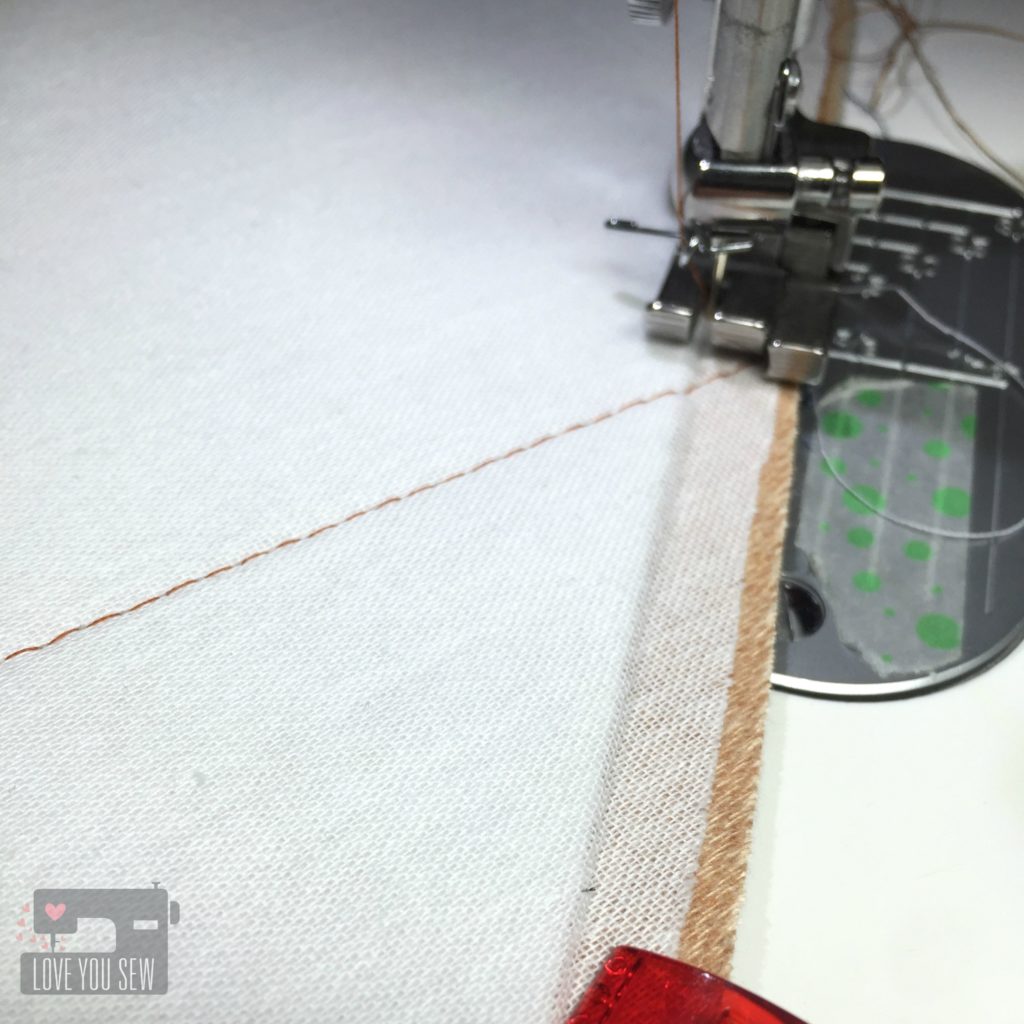

Like most other quilting, I made sure to use my walking foot and created long thread tails to hide later on. I used all Gutermann polyester thread.

I used rivets all around the border of the flap to add the extra “edge” on this bag. Initially, I was going to use nickel hardware (because that’s what I had on-hand,) but Sara helped me decide on the gunmetal and just wait to finish my bag later. Yeah…that was a pretty good decision.

The slider and rectangle rings were quickly ordered and boy…do they make the bag. 🙂 The gunmetal really works with the feel I was going for with this bag.

So….of course, I added a few extra rivets around to balance out the front flap. Also, I made two strap extenders instead of just one. After having the bag sit around waiting for the hardware, I thought I would use this more as a cross-body than an under-the-arm bag. It just works more with my lifestyle with active young kids.

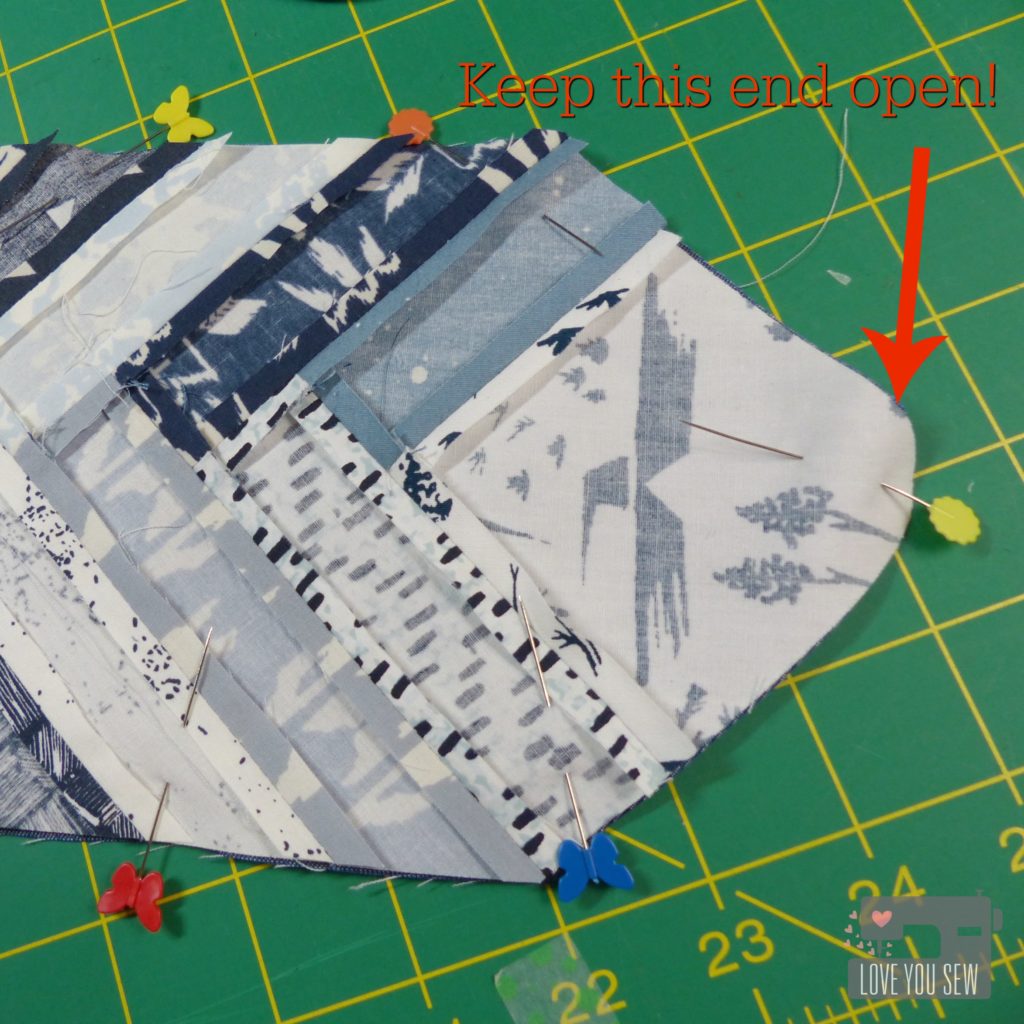

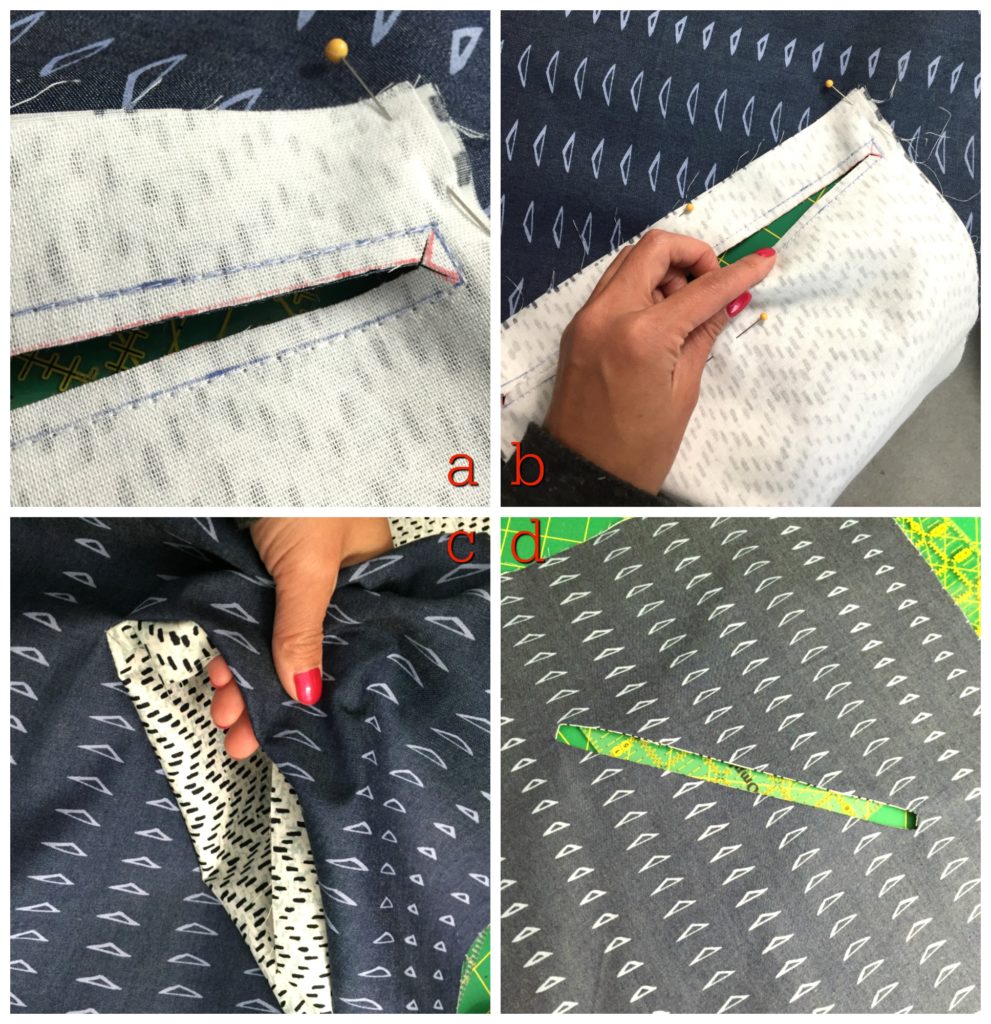

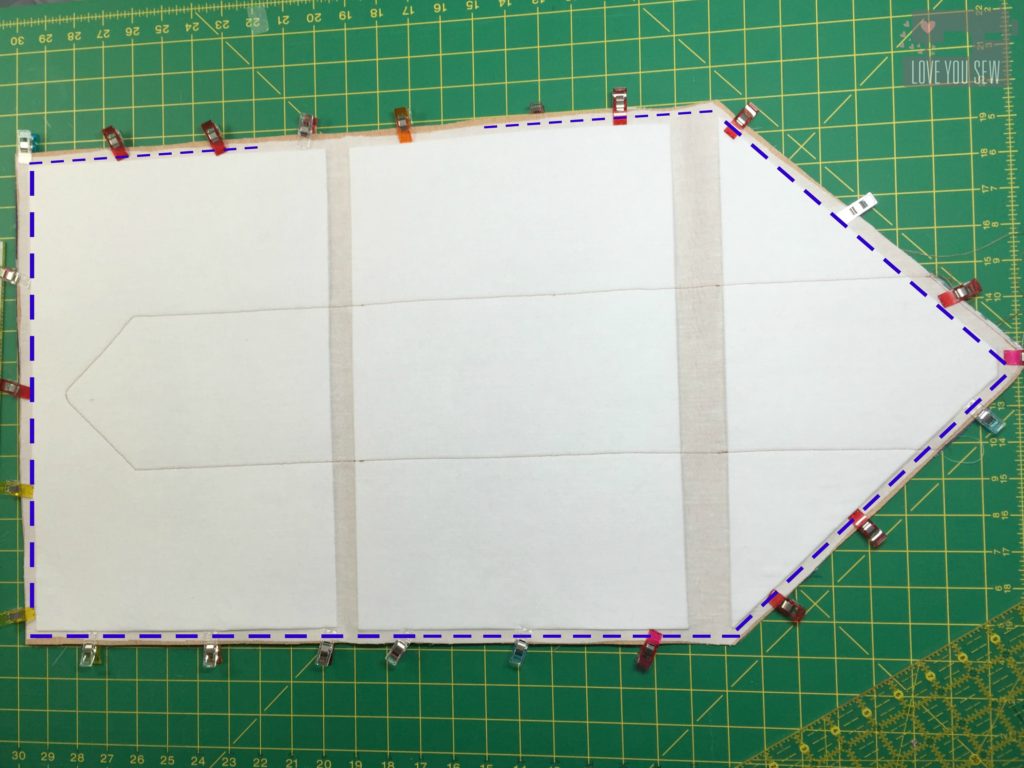

Having Sara around to instruct and so many nice bagineers to assist, the Appaloosa came together so quickly. We definitely didn’t need the full 6 hours at all. The most challenging part was just sewing through all the layers of the front accordion pockets to the sides of the bag. I would definitely recommend some large needles and to hand-crank it if needed.

I love the multiple pockets in the front of the bag…and there is still another zip pocket in the main compartment. Since I used a metal zipper, I did run into the issue of having to shorten and adjust the one had even though it was a 9″ as called for in the pattern.

The back of the Appaloosa is nice and smooth. With all the pockets on the front, you really don’t need anything on the back. Although….once I get my new black leather labels, this bag will definitely get one toward the top-center of the back.

Verdict – I love this design! Initially, it wasn’t for me, but I made it my own. It made me think out of the box a little bit and now I want to go through all the patterns I own and take a look at each one differently and how I can own each one. It’s amazing what the fabric and some hardware can do to completely change up a bag.

For the Appaloosa bag, you can purchase the pattern and/or the instructional video here.

Please note there are affiliate links in this post. I will only ever link to products I have used myself and as always give you the real deal in my opinions and experiences.